Understanding GWP, PFAS, and Their Environmental Impact

Greenhouse gases play a pivotal role in shaping Earth’s climate and future endeavours to address, with their varying potency influencing global warming.

The Global Warming Potential (GWP) serves as a crucial metric for comparing the warming effects of different gases relative to carbon dioxide (CO2).

What is GWP?

The Global Warming Potential (GWP) was developed to allow comparisons of the global warming impacts of different gases.

Specifically, it measures how much energy the emissions of 1 ton (unit of measure) of a gas will absorb over a given period, relative to the emissions of 1 ton of CO2 over consideration of 20 years or 100 years.

The larger the GWP, the more a given gas warms the Earth compared to CO2 over that period.

The standard period for GWPs is 100 years but recent analysis considers 20 years as a more appropriate measure with the goal of net zero called for in the Paris Agreement.

CO2 is used as a baseline reference gas, which has a GWP of 1 regardless of the time period used on this particular gas.

Updates to GWP Values

The Intergovernmental Panel on Climate Change (IPCC) periodically updates GWP values based on scientific advancements. Currently, GWP values used in international greenhouse gas reporting align with the Fifth Assessment Report (AR5) of the IPCC.

Understanding PFAS

Per- and polyfluoroalkyl substances (PFAS) encompass a diverse group of chemicals previously prized for their heat, stain, grease, and water resistance. They are used widely across several industries, including fire-fighting foams, textiles, coatings, cosmetics and refrigerants (HFC) to name a few applications.

Environmental Concerns

PFAS pose environmental challenges and increased focus on from Global Environmental Agency due to their high mobility in water, resistance to natural degradation, and toxicity to various organisms. Increased levels of PFAS have been detected at sites like airports, defence bases, and water treatment facilities prompting global efforts to phase out their use.

Regulatory Landscape

Governments worldwide are adopting stricter regulations to address PFAS contamination. Global manufacturers will need to consider the restrictive requirements to maintain market access, driving a shift towards PFAS-free alternatives.

Focus and Impact of International Agreements

Hydrofluorocarbons (HFCs) are subject to an international agreement to significantly phase down production and bulk imports under the Kigali Amendment to the Montreal Protocol. Under the agreement, participating countries, including Australia, are restricted by a diminishing quota system that limits bulk imports of HFCs. Although HFCs used in pre-charged equipment are accounted for in the country of manufacture, ongoing servicing, and end-of-life management of this growing technology.

To date there have been few restrictions on the GWP of refrigerants in heat pump equipment however this is changing with international and Australian regulations, starting: From 1 July 2024 the Australian Government prohibit using refrigerant with a GWP over 750.

Further Focus

The trend towards PFAS and HFC elimination underscores the need for proactive measures from government, manufacturers and consumers.

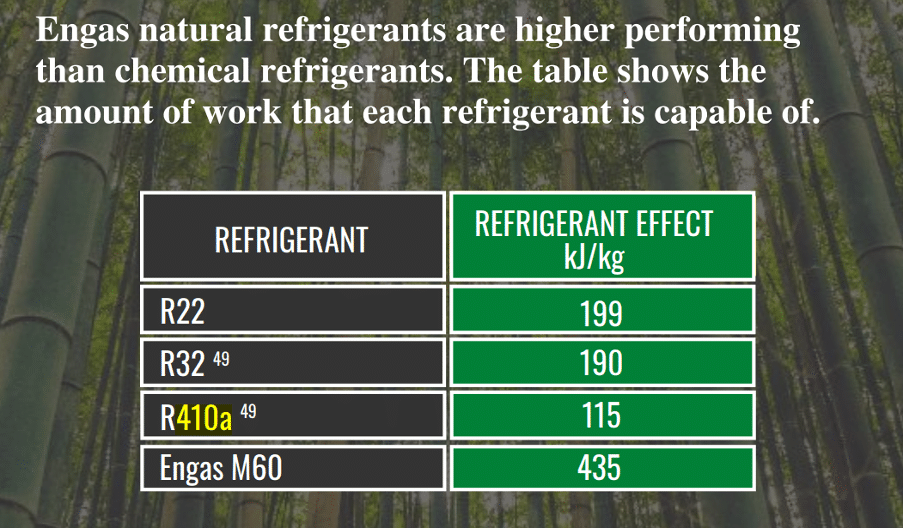

Hydrocarbon refrigerants like M60 are natural refrigerants are forefront in this space, offering a remarkable 50% increase in heat conductivity compared to synthetic refrigerants. This translates directly into substantial energy savings ranging from 17% to 54%, providing an efficient and cost-effective solution for environmentally sustainable solutions for businesses.

By considering and understanding the impact of Global Warming Potential and PFAS, we can work together to mitigate climate change and safeguard our environment for future generations.

Hydrocarbon Refrigerant’s (M60)

-

- Hydrocarbon Refrigerants are promoted for use by the United Nations Environment Programme.

-

- Hydrocarbon Refrigerants are recognised as proper refrigerants by the World’s leading HVAC Industry Bodies such as ASHRAE & AIRAH. They are given designated ‘R’ numbers such as R290 & R600a etc.

-

- Hydrocarbon Refrigerants are environmentally friendly.

-

- Hydrocarbon Refrigerants are energy efficient.

-

- Hydrocarbon Refrigerants have lower operating temperatures and excellent lubricating properties. Therefore, the compressors run cooler, quieter and with less vibration.

Hydrocarbons offer favourable thermodynamic refrigerant properties that make them highly efficient. These include low liquid and vapour viscosities, high liquid-specific heat, high liquid and vapour thermal conductivities and high latent heat.